TPEE Insulated PUR Sheathed Cables, 300/500V

Application

These cables are used as power and control cables or connecting cables. They are suitable for automatic production line, control unit, factory cabling, office equipment, etc.

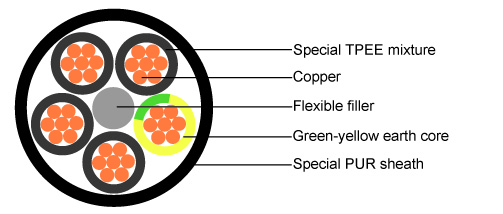

Cable Construction

| Conductor | VDE0295 Class 6 |

| Insulation | Special high-strength TPEE mixture |

| Center filler | Flexible filler |

| Sheath | Special low viscosity wear resistant PUR mixture |

Technical Properties

- Voltage: 300/500V

- Test voltage: 2000V/5min(AC)

- Minimum bend radius: Fixed installation: 4xOD

- Temperature range: Fixed installation: -50~90℃

- Retardant properties: Complied with IEC60332-1

Dimensions and Weight

| No.of Cores | Conductor Cross-Sectional Area | Strands Number and Dia. of Wires | Nominal Dia. of Cable | Max. Dia. of Cable | Approx. Weight |

| mm² | No./mm | mm | mm | kg/km | |

| 2 | 0.25 | 19/0.13 | 4.2 | 5.0 | 22 |

| 3 | 0.25 | 19/0.13 | 4.3 | 5.1 | 26 |

| 4 | 0.25 | 19/0.13 | 4.6 | 5.4 | 31 |

| 5 | 0.25 | 19/0.13 | 4.9 | 5.7 | 36 |

| 6 | 0.25 | 19/0.13 | 5.2 | 6.0 | 41 |

| 7 | 0.25 | 19/0.13 | 5.2 | 6.0 | 43 |

| 8 | 0.25 | 19/0.13 | 5.5 | 6.3 | 48 |

| 10 | 0.25 | 19/0.13 | 6.5 | 7.3 | 61 |

| 12 | 0.25 | 19/0.13 | 6.6 | 7.4 | 68 |

| 14 | 0.25 | 19/0.13 | 6.9 | 7.6 | 76 |

| 2 | 0.34 | 19/0.15 | 4.7 | 5.5 | 29 |

| 3 | 0.34 | 19/0.15 | 4.9 | 5.7 | 33 |

| 4 | 0.34 | 19/0.15 | 5.2 | 6.0 | 39 |

| 5 | 0.34 | 19/0.15 | 5.8 | 6.6 | 49 |

| 6 | 0.34 | 19/0.15 | 6.2 | 7.0 | 55 |

| 7 | 0.34 | 19/0.15 | 6.2 | 7.0 | 59 |

| 8 | 0.34 | 19/0.15 | 6.6 | 7.4 | 66 |

| 10 | 0.34 | 19/0.15 | 7.5 | 8.4 | 81 |

| 12 | 0.34 | 19/0.15 | 7.7 | 8.6 | 89 |

| 14 | 0.34 | 19/0.15 | 8.0 | 9.0 | 100 |

| 16 | 0.34 | 19/0.15 | 8.6 | 9.8 | 116 |

| 18 | 0.34 | 19/0.15 | 9.0 | 10.0 | 127 |

| 20 | 0.34 | 19/0.15 | 9.3 | 10.3 | 139 |

| 24 | 0.34 | 19/0.15 | 10.2 | 11.3 | 162 |

| 25 | 0.34 | 19/0.15 | 10.4 | 11.5 | 166 |

| 30 | 0.34 | 19/0.15 | 10.8 | 11.9 | 191 |

| 36 | 0.34 | 19/0.15 | 11.7 | 12.9 | 229 |

| 2 | 0.5 | 16/0.20 | 5.1 | 5.9 | 35 |

| 3 | 0.5 | 16/0.20 | 5.4 | 6.2 | 41 |

| 4 | 0.5 | 16/0.20 | 6.0 | 6.8 | 52 |

| 5 | 0.5 | 16/0.20 | 6.4 | 7.2 | 61 |

| 6 | 0.5 | 16/0.20 | 6.9 | 7.7 | 70 |

| 7 | 0.5 | 16/0.20 | 6.9 | 7.7 | 75 |

| 8 | 0.5 | 16/0.20 | 7.3 | 8.1 | 85 |

| 10 | 0.5 | 16/0.20 | 8.6 | 9.5 | 108 |

| 12 | 0.5 | 16/0.20 | 8.8 | 9.7 | 120 |

| 14 | 0.5 | 16/0.20 | 9.2 | 10.1 | 135 |

| 16 | 0.5 | 16/0.20 | 9.6 | 10.6 | 151 |

| 18 | 0.5 | 16/0.20 | 10.1 | 11.1 | 167 |

| 20 | 0.5 | 16/0.20 | 10.6 | 11.6 | 183 |

| 24 | 0.5 | 16/0.20 | 11.8 | 13.0 | 219 |

| 25 | 0.5 | 16/0.20 | 12.1 | 13.3 | 226 |

| 30 | 0.5 | 16/0.20 | 12.4 | 13.7 | 260 |

| 36 | 0.5 | 16/0.20 | 13.3 | 14.7 | 305 |

| 2 | 0.75 | 24/0.20 | 5.8 | 6.6 | 45 |

| 3 | 0.75 | 24/0.20 | 6.0 | 6.8 | 56 |

| 4 | 0.75 | 24/0.20 | 6.5 | 7.3 | 65 |

| 5 | 0.75 | 24/0.20 | 7.0 | 7.8 | 77 |

| 6 | 0.75 | 24/0.20 | 7.5 | 8.3 | 90 |

| 7 | 0.75 | 24/0.20 | 7.5 | 8.3 | 97 |

| 8 | 0.75 | 24/0.20 | 8.0 | 8.8 | 109 |

| 10 | 0.75 | 24/0.20 | 9.4 | 10.4 | 139 |

| 12 | 0.75 | 24/0.20 | 9.7 | 10.7 | 159 |

| 14 | 0.75 | 24/0.20 | 10.1 | 11.1 | 177 |

| 16 | 0.75 | 24/0.20 | 10.6 | 11.7 | 199 |

| 18 | 0.75 | 24/0.20 | 11.4 | 12.5 | 225 |

| 20 | 0.75 | 24/0.20 | 11.9 | 13.1 | 249 |

| 24 | 0.75 | 24/0.20 | 13.1 | 14.4 | 290 |

| 25 | 0.75 | 24/0.20 | 13.3 | 14.7 | 299 |

| 30 | 0.75 | 24/0.20 | 14.0 | 15.4 | 353 |

| 36 | 0.75 | 24/0.20 | 15.0 | 16.5 | 415 |

| 2 | 1 | 32/0.20 | 6.3 | 7.1 | 54 |

| 3 | 1 | 32/0.20 | 6.6 | 7.4 | 59 |

| 4 | 1 | 32/0.20 | 7.1 | 7.9 | 84 |

| 5 | 1 | 32/0.20 | 7.7 | 8.5 | 96 |

| 6 | 1 | 32/0.20 | 8.5 | 9.4 | 115 |

| 7 | 1 | 32/0.20 | 8.5 | 9.4 | 125 |

| 8 | 1 | 32/0.20 | 9.1 | 10.0 | 142 |

| 10 | 1 | 32/0.20 | 10.5 | 11.6 | 175 |

| 12 | 1 | 32/0.20 | 10.8 | 11.9 | 201 |

| 14 | 1 | 32/0.20 | 11.5 | 12.7 | 231 |

| 16 | 1 | 32/0.20 | 12.1 | 13.3 | 258 |

| 18 | 1 | 32/0.20 | 12.7 | 14.0 | 287 |

| 20 | 1 | 32/0.20 | 13.3 | 14.6 | 317 |

| 24 | 1 | 32/0.20 | 14.9 | 16.4 | 317 |

| 25 | 1 | 32/0.20 | 15.2 | 16.7 | 389 |

| 30 | 1 | 32/0.20 | 15.7 | 17.3 | 453 |

| 36 | 1 | 32/0.20 | 17.1 | 18.8 | 541 |

| 2 | 1.5 | 48/0.20 | 7.1 | 8.0 | 70 |

| 3 | 1.5 | 48/0.20 | 7.5 | 8.4 | 90 |

| 4 | 1.5 | 48/0.20 | 8.1 | 9.0 | 111 |

| 5 | 1.5 | 48/0.20 | 9.0 | 9.9 | 134 |

| 6 | 1.5 | 48/0.20 | 9.7 | 10.7 | 158 |

| 7 | 1.5 | 48/0.20 | 9.7 | 10.7 | 171 |

| 8 | 1.5 | 48/0.20 | 10.4 | 11.5 | 194 |

| 10 | 1.5 | 48/0.20 | 12.3 | 13.5 | 246 |

| 12 | 1.5 | 48/0.20 | 12.7 | 13.9 | 284 |

| 14 | 1.5 | 48/0.20 | 13.3 | 14.6 | 320 |

| 16 | 1.5 | 48/0.20 | 14.2 | 15.6 | 366 |

| 18 | 1.5 | 48/0.20 | 14.9 | 16.4 | 408 |

| 20 | 1.5 | 48/0.20 | 15.6 | 17.2 | 448 |

| 24 | 1.5 | 48/0.20 | 17.5 | 19.3 | 536 |

| 25 | 1.5 | 48/0.20 | 17.9 | 19.7 | 552 |

| 30 | 1.5 | 48/0.20 | 18.5 | 20.3 | 646 |

| 36 | 1.5 | 48/0.20 | 20.1 | 22.1 | 772 |

| 2 | 2.5 | 77/0.20 | 8.1 | 9.0 | 94 |

| 3 | 2.5 | 77/0.20 | 8.7 | 9.6 | 127 |

| 4 | 2.5 | 77/0.20 | 9.5 | 10.5 | 161 |

| 5 | 2.5 | 77/0.20 | 10.3 | 11.4 | 188 |

| 6 | 2.5 | 77/0.20 | 11.4 | 12.5 | 227 |

| 7 | 2.5 | 77/0.20 | 11.4 | 12.5 | 249 |

| 8 | 2.5 | 77/0.20 | 12.3 | 13.5 | 282 |

| 10 | 2.5 | 77/0.20 | 14.5 | 16.0 | 357 |

| 12 | 2.5 | 77/0.20 | 14.9 | 16.4 | 410 |

| 14 | 2.5 | 77/0.20 | 15.7 | 17.3 | 475 |

| 16 | 2.5 | 77/0.20 | 16.7 | 18.4 | 536 |

| 18 | 2.5 | 77/0.20 | 17.6 | 19.4 | 599 |

| 20 | 2.5 | 77/0.20 | 18.5 | 20.3 | 659 |

| 24 | 2.5 | 77/0.20 | 20.7 | 22.8 | 788 |

| 25 | 2.5 | 77/0.20 | 21.1 | 23.3 | 814 |

| 30 | 2.5 | 77/0.20 | 22.1 | 24.3 | 964 |

| 36 | 2.5 | 77/0.20 | 23.8 | 26.2 | 1142 |